Click on the images to enlarge.

2019-03-02

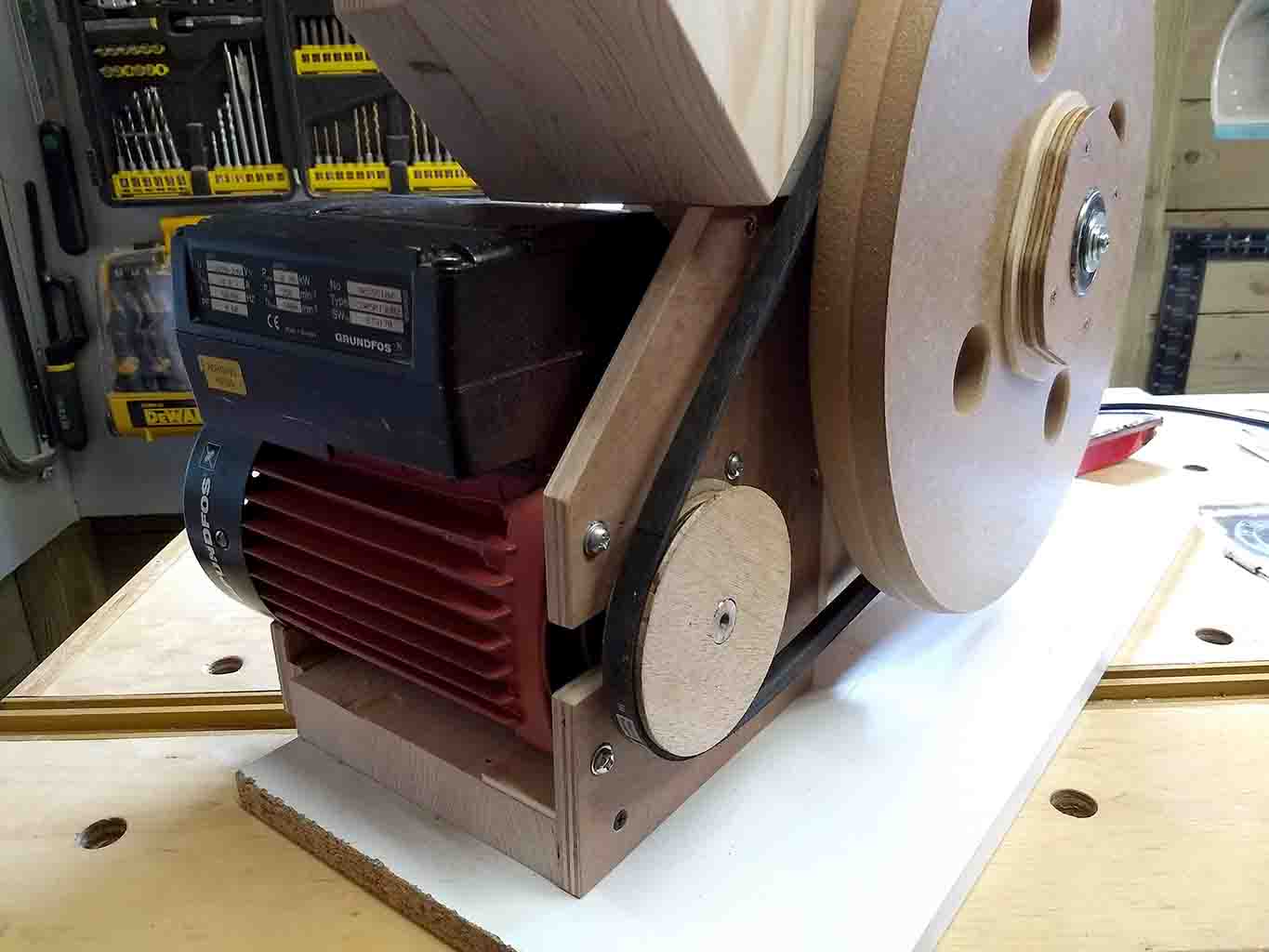

I bought a very nice secondhand motor: 1 HP, 1400 RPM with variable speed. As you can see it is a bit big; the "control unit" sticks out on top so I had to remove about 6 mm from the frame. And it doesn't have a mount for bolting it to the frame so I had to get creative with some plywood.

Because of the variable speed, cutting steel and aluminium should be possible as well. Some Googling showed that for steel you need about 80-300 FPM (feet per minute), for aluminium 1000 FPM and for wood 1000-1500 FPM.

To calculate the Blade speed in Feet Per Minute you can use this formula: Motor RPM x Motor Pulley Diam / Driven Pulley Diam x Band Saw Wheel Diam x 3.14 / 12.

For my 1400 rpm motor, I chose a 100 mm motor pulley. That should give a maximum speed of about 1900 FPM, which should be plenty of range.

I also bought a tachometer on Ebay so I know what speed I'm at, more on that later in the build.

First assembly of the frame with the motor and the wheels.

2019-03-29

We have five cats - Amir (brown) and Boaz (grey) like to drop by sometimes and check up on my progress. Amir is probably the weirdest of the lot...

2019-06-09

I needed about 0.75 millimeters of adjustment on the guide bar mount. Five layers of electrical tape fixed that nicely.

2019-08-09

After some use, this is the amount of dust gathered around the lower blade guard. Not too bad, but still some dust extraction would be nice. [Note: I added this at a later stage, see the Enclosure section for details]

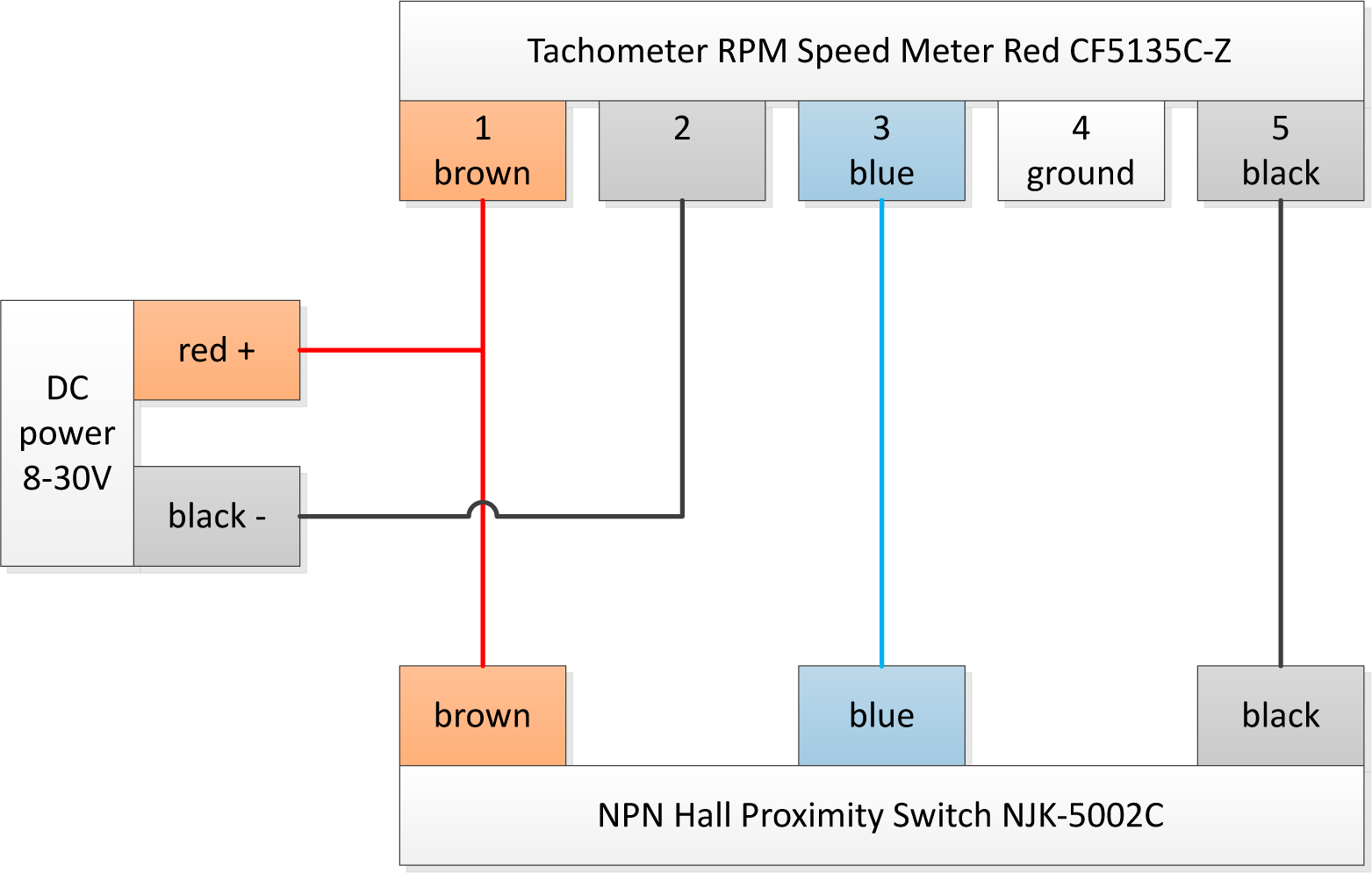

The cheap tachometer I ordered from Ebay, consists of a Tachometer RPM Speed Meter Red CF5135C-Z and an NPN Hall Proximity Switch NJK-5002C. And of course it came without instructions.

Luckily Ivan posted a schematic of this exact same combination on https://usefulldata.com/led-spedometer-cf5135b/. I have made a digital version of the paper schematic he posted.

2019-08-16

The on/off switch, the tachometer and the variable speed knob, in their own separate enclosure. I quite like the "bolted on" look that is happening here, sort of a "home-made industrial" style... And it all actually works as well! I expected it to, but still a small victory ;-)

One thing to keep in mind is that the sensor only works on one side of the magnet. And of course Murphy made sure my 50% chance of getting that (accidentally) right the first time didn't happen...

It turns out I have a range of 134 to 537 RPM, which translates to about 550 to 2200 FPM (feet per minute). A bit faster than I expected (and not as much range as I had hoped), so maybe I will change the pulley sizes later - but for now this works just fine. [Note: I did this at a later stage, see the Wheels section for details]

2019-09-28

I took the entire thing apart to apply laquer (frame and wheels) and Danish oil (all other parts). This puzzle sure has a lot of pieces...

2020-01-17

A cheap and cheerful USB chargeable LED lamp - really meant for reading books I guess - from Amazon. I made a simple mount for it so it can be easily removed for charging or if it's in the way.

2021-01-20

I think I abused the previous 2 sawblades a bit too much with my metal-cutting experiments, so they are now quite dull. I can stall the bandsaw quite easily with just a 20mm thick piece of plywood... So I ordered 2 new sawblades. In the Netherlands this time, because Tuffsaws (in the UK) does not ship abroad at this moment. Let's not discuss Brexit. Maybe I shouldn't even mention it, it's too depressing.

Anyway, I went for a lower TPI this time - a 6mm 6tpi blade (previously 6mm 10tpi) and a 16mm 4tpi blade (previously 12mm 6tpi). The larger teeth should help with sawdust removal (and therefore prevent stalling). So far so good, they work like a charm.